ENFIX 520 TDS

Description:

ENIFIX 520 is a one component adhesive developed specially for XLPE, NBR, Nitrile & EPDM rubber insulation material. It is ideal for Closed Cell & PE Cross Link Foam Insulation System. ENIFIX 520 is made from a combination of special resins & additives that produce an extremely low odor and provides excellent tack properties along with a very strong bond.

- Excellent Bonding to Porous & Non-Porous Surfaces

- Quick Drying and Setting Time

- Excellent Heat Resistance

- Extremely Low Odor

- Chemical Resistant

- Excellent Tack

- UV Resistant

Recommended Applications(ENFIX 520)

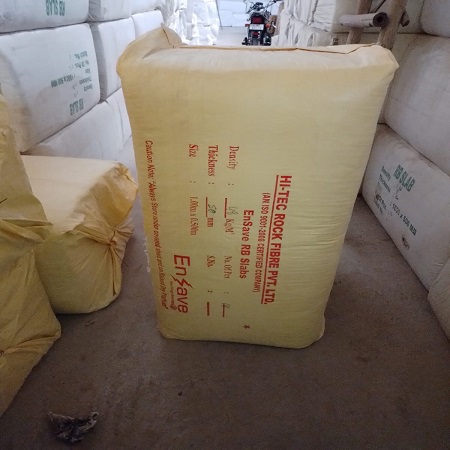

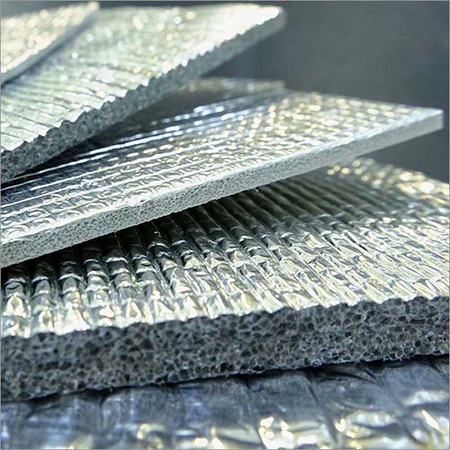

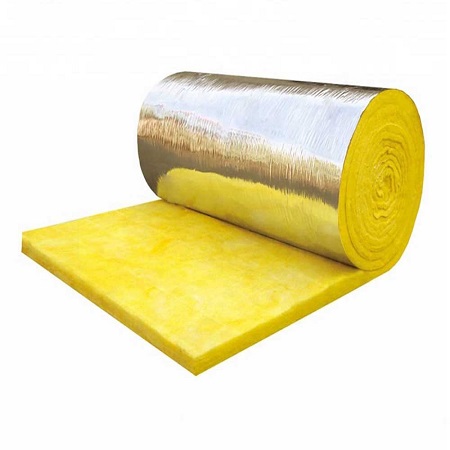

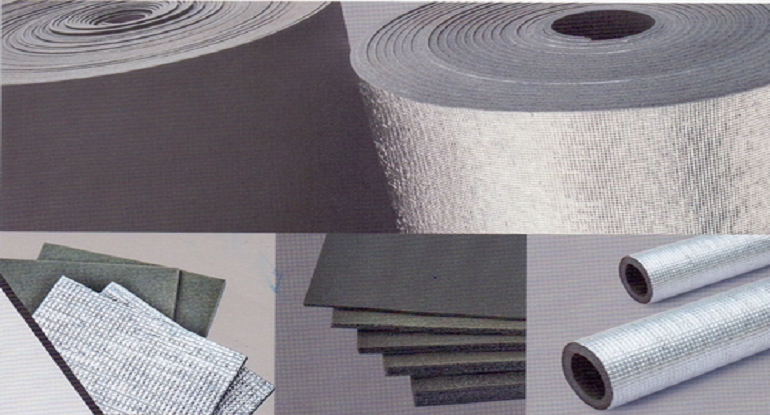

ENIFIX 520 is used for air duct insulation, pipe sections, slabs, under deck (metal, concrete), etc.

ENIFIX 520 is an ideal product for bonding:

ENIFIX 520 is an ideal product for bonding:

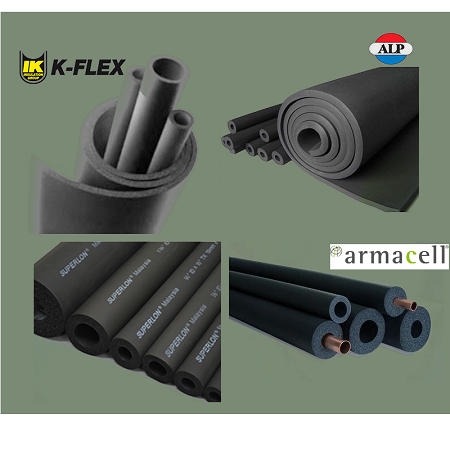

- NBR Insulation to MS Pipe

- XLPE Insulation to MS Pipe

- NBR Insulation in Underdeck

- XLPE Insulation in Underdeck

- Nitrile & EPDM Rubber Insulation

- Closed Cell & PE Cross Link Foam Insulation System

Conforms To:

- Military Spec. MIL-A-24179A, Class 1, Type 2

- NFPA 90A and 90B 25/50

- Free of asbestos, lead and mercury compounds

SPECIFICATION DATA:

- Colour: Yellow / Black

- SPhysical form: Liquid

- Specific Gravity (ASTM D 1475-98): 0.83±0.05 kg/ltr

- Solids Content (ASTM D 1644): 20±2 %

- Viscosity (ASTM D 2196): 800-1200 cPs

- Flash Point (ASTM D 92): Flash Point <10oC

- Drying Time (ASTM D 1640): Set to Touch: 10-15 Minutes Complete Bond: 30 Minutes

- Service Temperature: Minus 25oC to 120oC

- Coverage Range (subject to surface condition): 5 – 8 m2/ltr

- Application: Brush or Roller

Surface Preparation:

The surface to be bonded should be structurally sound, clean, dry, leveled and free from dust, curing compounds, grease and other loose debris. Keep container closed when not in use.

Application Procedure:

Apply ENIFIX 520 evenly on both surfaces using a brush or roller. Allow the surface to become tacky & dry. After both surfaces are dry, bring them together and join by applying normal pressure.

Packaging:

30, 25 & 5 Ltr Metal Can

Shelf Life:

12 months from date of manufacturing in original unopened containers.

Storage:

Store product (10oC - 30oC) for maximum storage life. Higher temperatures reduce normal storage life. Lower temperatures may cause increased viscosity of a temporary nature. Rotate stock on a “first in-first out” basis.Failure to comply with the recommended storage conditions may result in premature deterioration of the product or packaging.

Cleaning:

Clean tools immediately after use with thinner. Immediately remove any adhesive from the surface of the floor covering with a damp cloth soaked in thinner.

Health & Safety:

Consult Material Safety Data Sheet and container label for further information.

Our Gallery

For any enquiry

Call now: + 91 77038 55198

Contact Us

Mobile

+91-99530 37466

+91- 77038 55198

Company Name

ANAND ENTERPRISES

Address

Plot No-6,Pocket-7,Sector-12,Dwarka,New Delhi-75

Phone

+91-99530 37466,

+91 77038 55198